- Home

- Paver Block PVC Rubber Mould

Paver Block PVC Rubber Mould

Colorado

Cosmic

Hexagone

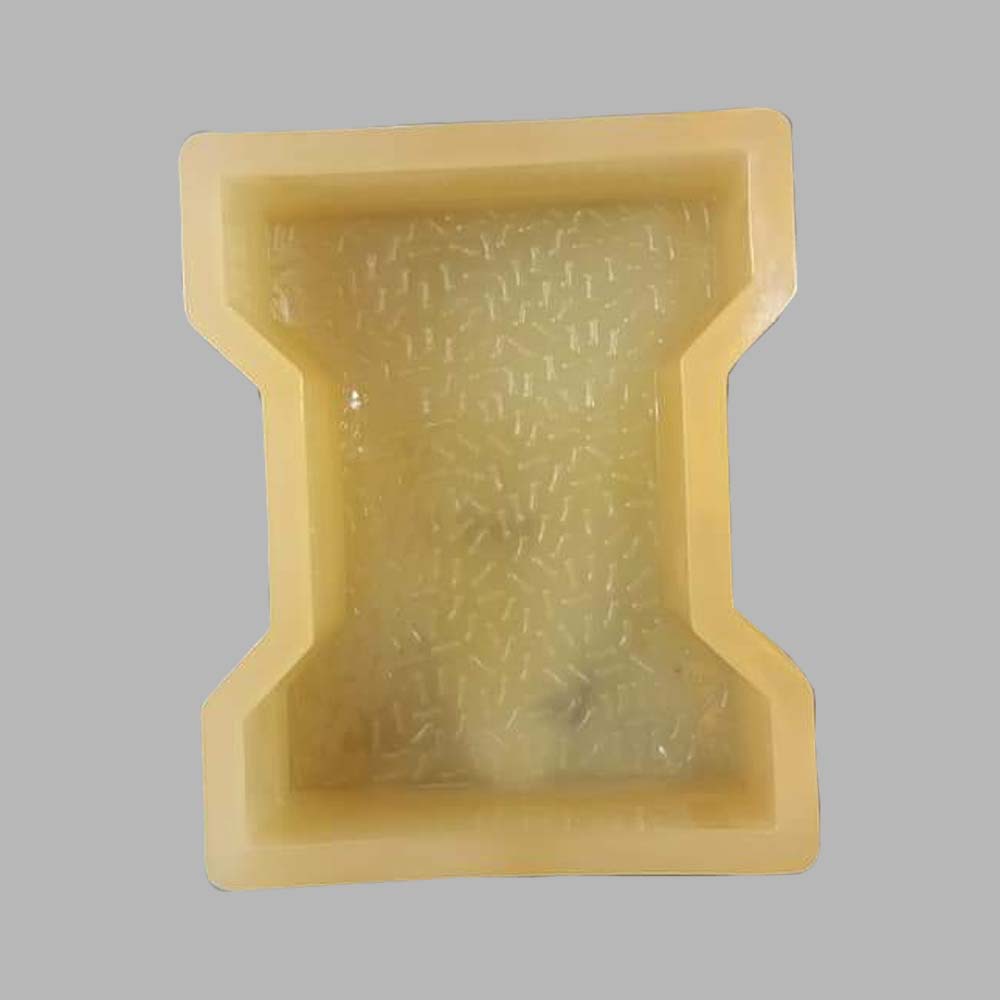

I Paver

Zig-Zag

Using PVC molds for paver and tile manufacturing offers several benefits:

Cost-effectiveness: PVC molds are relatively inexpensive compared to metal or rubber molds, reducing production costs.

Durability: PVC molds are durable and can withstand repeated use without significant wear or damage, ensuring consistent quality over time.

Flexibility: PVC molds can be easily customized to create various shapes, sizes, and textures for pavers and tiles, providing versatility in design options.

Ease of release: PVC molds have excellent release properties, allowing for easy removal of finished pavers and tiles without sticking or deformation.

Lightweight: PVC molds are lightweight, making them easier to handle and transport compared to heavier materials like metal or concrete molds.

Quick production: PVC molds can be produced quickly and efficiently, reducing lead times and increasing manufacturing efficiency.

Resistance to moisture and chemicals: PVC molds are resistant to moisture and chemicals, ensuring the longevity of the molds even in harsh manufacturing environments.

Low maintenance: PVC molds require minimal maintenance, as they do not corrode or degrade over time like metal molds, reducing downtime and maintenance costs.

Recyclability: PVC is recyclable, making it an environmentally friendly option for mold manufacturing, reducing waste and environmental impact.

Overall, PVC paver and tile molds offer a cost-effective, durable, and versatile solution for manufacturers in the construction industry, helping to streamline production processes and maintain high-quality standards